Banana Fiber Can Make Many Different Textiles. This fiber is a natural and eco-friendly material that can be used to create various fabrics and products and sustainable rural entrepreneurship

Prof. Aécio D’Silva, Ph.D

AquaUniversity

Banana fiber is extracted from the waste parts of the banana plant, such as the stem and the leaves. It is a strong, soft, and biodegradable fiber that can be spun into yarns and woven into fabrics. This fiber can be used to make many different textiles, such as clothing, accessories, paper, and furniture. The fiber has many advantages, such as being renewable, low-cost, and versatile. It also has a positive impact on the environment and society, as it reduces waste, saves water, and provides income and employment opportunities.

Banana is one of the most popular and widely consumed fruits in the world, with an annual production of about 125 million tons in 2021. The global banana market size is estimated to reach USD 140.84 billion in 2024 [1, 1a]

However, only the fruit is used for human consumption, while the rest of the plant, such as the stem and the leaves, is usually discarded or burned, causing environmental problems and waste of resources. According to a study by the Clean Technologies and Environmental Policy journal, over a billion tons of banana plant stems are thrown away every year. [2]

However, these waste parts of the banana plant can be a valuable source of natural fiber, which can be used to create various fabrics and products. Banana fiber is a natural and eco-friendly material that can be extracted from the stem and the leaves of the banana plant, using mechanical or chemical methods. This fiber is a strong, soft, and biodegradable fiber that can be spun into yarns and woven into fabrics. Banana fiber can be used to make many different textiles, such as clothing, accessories, paper, and furniture.

The fiber has many advantages, such as being renewable, low-cost, and versatile. It also has a positive impact on the environment and society, as it reduces waste, saves water, and provides income and employment opportunities. In this blog post, we will explain what banana fiber is, how it is made, and what are its applications and benefits.

What is Banana Fiber

This fiber is a natural fiber that is extracted from the stem and the leaves of the banana plant. Banana fiber is also known as musa fiber, as the scientific name of the banana plant is Musa spp. Banana fiber is composed of cellulose, hemicellulose, and lignin, which are the main components of plant fibers. Banana fiber has a natural shine and a silky texture, similar to silk. Banana fiber is also durable and flexible, like hemp. Banana fiber can be dyed with natural or synthetic dyes and can be blended with other fibers, such as cotton, silk, or polyester.

This fiber can be classified into three types, depending on the part of the plant and the extraction method:

- Leaf fiber: This is the fiber extracted from the banana plant’s leaves, using a mechanical process. Leaf fiber is coarse and stiff and has a brown color. Leaf fiber is mainly used for making ropes, mats, baskets, and other coarse products.

- Pseudo-stem fiber: This is the fiber that is extracted from the pseudo-stem of the banana plant, which is the trunk-like part that supports the leaves and the fruit. Pseudo-stem fiber can be extracted using a mechanical or a chemical process. Mechanical extraction involves stripping, scraping, and drying the pseudo-stem, while chemical extraction involves soaking, boiling, and bleaching the pseudo-stem. Pseudo-stem fiber is fine and soft and has a white or cream color. Pseudo-stem fiber is mainly used for making clothing, accessories, paper, and other fine products.

- Bast fiber: This is the fiber that is extracted from the inner bark of the banana plant, using a mechanical process. Bast fiber is fine and strong and has a white or yellow color. Bast fiber is mainly used for making paper, furniture, and other strong products. [3]

How to Make Banana Fiber

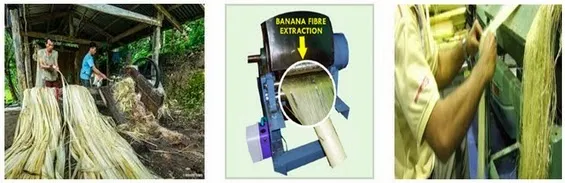

The process of making this fiber varies depending on the type of fiber and the extraction method. However, the general steps are as follows:

- Harvesting: The first step is to harvest the banana plant after the fruit is ripe and collected. The banana plant can only produce fruit once in its lifetime, so it is usually cut down after the harvest. The stem and the leaves of the banana plant are then separated and collected for fiber extraction.

- Extraction: The second step is to extract the fiber from the stem and the leaves of the banana plant, using a mechanical or a chemical method. Mechanical extraction involves using a knife, a scraper, or a machine to peel off the outer layers of the stem and the leaves, and then pulling out the fibers by hand or by a machine. Chemical extraction involves using water, alkali, or enzymes to soften and dissolve the outer layers of the stem, and then washing and drying the fibers.

- Cleaning: The third step is to clean the fiber from any impurities, such as dirt, dust, or residual plant material. Cleaning can be done by washing, rinsing, and drying the fiber, using water, soap, or bleach.

- Spinning: The fourth step is to spin the fiber into yarns, using a hand spindle or a spinning machine. Spinning involves twisting and winding the fiber into a continuous thread, which can be used for weaving or knitting. Spinning can also involve blending the fiber with other fibers, such as cotton, silk, or polyester, to improve the quality and properties of the yarn.

- Weaving: The fifth step is to weave the yarn into fabrics, using a handloom or a weaving machine. Weaving involves interlacing the yarns into a flat and flexible material, which can be used for making various products. Weaving can also involve dyeing the yarn or the fabric, using natural or synthetic dyes, to add color and design to the fabric.

How to make chemical extraction of banana fiber

Chemical extraction is a method that uses water, alkali, or enzymes to soften and dissolve the outer layers of the stem, and then wash and dry the fibers. Chemical extraction can produce finer and softer fibers than mechanical extraction, but it can also cause environmental pollution and fiber damage. Here are the main steps of chemical extraction:

- Soaking: The stem of the banana plant is cut into small pieces and soaked in water for several hours or days, depending on the type and maturity of the plant. This step helps to loosen the fiber bundles and remove some of the impurities, such as dirt, dust, and pigments.

- Boiling: The soaked stem pieces are boiled in an alkaline solution, such as sodium hydroxide or potassium hydroxide, for a few hours, depending on the concentration and temperature of the solution. This step helps to break down the lignin and hemicellulose, which are the main components of the gum that bind the fiber bundles. The boiling also helps to bleach and sanitize the fibers.

- Washing: The boiled stem pieces are washed with water to remove the excess alkali and the dissolved gum. The washing can be done by hand or by a machine, such as a centrifuge or a hydro-extractor. The washing also helps to improve the whiteness and the softness of the fibers.

- Drying: The washed stem pieces are dried in the sun or in an oven to remove the moisture and to prevent the growth of mold and bacteria. The drying can be done by spreading the stem pieces on a flat surface or by hanging them on a rack. The drying also helps to preserve and store the fibers.

- Separating: The dried stem pieces are separated into individual fibers by hand or by a machine, such as a comb or a decorticator. The separating also helps to remove any remaining impurities, such as broken fibers, coating of cellulose, or residual gum.

Chemical extraction is one of the methods to produce this fiber from the stem of the banana plant. It can produce fine and soft fibers that can be used for making clothing, accessories, paper, and other fine products. However, chemical extraction also has some disadvantages, such as causing environmental pollution, consuming more water and energy, and damaging the fiber quality and strength. [3, 4]

Applications and Benefits of Banana Fiber

This fiber can be used to make many different textiles, such as clothing, accessories, paper, and furniture. Banana fiber has many applications and benefits, such as:

- Clothing: This fiber can be used to make clothing, such as shirts, dresses, skirts, pants, jackets, and scarves. This fiber clothing is soft, smooth, and comfortable, similar to silk. This fiber clothing is also breathable, moisture-wicking, and antibacterial, like hemp. This fiber clothing is suitable for all seasons, as it can keep the body cool in summer and warm in winter. This fiber clothing is also durable, flexible, and biodegradable, making it a sustainable and eco-friendly choice.

- Accessories: Banana fiber can be used to make accessories, such as bags, hats, belts, wallets, and jewelry. This fiber accessories are stylish, elegant, and unique, as they have a natural shine and a silky texture. These fiber accessories are also lightweight, strong, and versatile, as they can be dyed and blended with other materials. Banana fiber accessories are also renewable, low-cost, and biodegradable, making them a sustainable and eco-friendly choice.

- Paper: This fiber can be used to make paper, such as writing paper, printing paper, wrapping paper, and tissue paper. Banana fiber paper is smooth, glossy, and high-quality, similar to bamboo paper. This fiber paper is also durable, tear-resistant, and water-resistant, similar to hemp paper. This fiber paper is suitable for various purposes, such as art, craft, education, and communication. This fiber paper is also recyclable, compostable, and biodegradable, making it a sustainable and eco-friendly choice.

- Furniture: Banana fiber can be used to make furniture, such as chairs, tables, sofas, and beds. This fiber furniture is attractive, cozy, and functional, as it has a natural and organic look and feel. This fiber furniture is also sturdy, flexible, and resilient, as it can withstand wear and tear and adapt to different shapes and sizes. Banana fiber furniture is suitable for indoor and outdoor use, as it can resist moisture and insects. Banana fiber furniture is also renewable, low-cost, and biodegradable, making it a sustainable and eco-friendly choice. [1, 2, 3, 4 ]

In Conclusion, In this blog post, we have explained what banana fiber is, how it is made, and what are its applications and benefits. We have shown that this a fiber is a natural and eco-friendly material that can be used to create various fabrics and products. Banana fiber is extracted from the waste parts of the banana plant, such as the stem and the leaves, using mechanical or chemical methods. Banana fiber is a strong, soft, and biodegradable fiber that can be spun into yarns and woven into fabrics. Banana fiber can be used to make many different textiles, such as clothing, accessories, paper, and furniture. Banana fiber has many advantages, such as being renewable, low-cost, and versatile. It also has a positive impact on the environment and society, as it reduces waste, saves water, and provides income and employment opportunities. Banana fiber is a sustainable textile innovation that can make many different textiles.

References

[1] FAO, “Banana market review 2019-2020”, 2020.

[2] Made Trade, “Banana Fiber: Transforming Banana Tree Waste Into Fabric”, 2019. https://www.madetrade.com/blogs/magazine/banana-fabric

[3] S. Balda, A. Sharma, N. Capalash, and P. Sharma, “Banana fibre: a natural and sustainable bioresource for eco-friendly applications”, Clean Technologies and Environmental Policy, vol. 23, pp. 1389-1401, 2021. https://link.springer.com/article/10.1007/s10098-021-02041-y.

[4] Kiron, M. (2021). Banana Fiber: Properties, Manufacturing Process and Applications. Southeast University. https://textilelearner.net/banana-fiber-properties-manufacturing/