Contents

- 1 A guide to the process and benefits of making banana fiber fabric from banana tree waste

- 2 Prof. Aécio D’Silva, Ph.D AquaUniversity

- 3 How to make fabric from banana tree waste

- 4

- 5 Benefits for you and the environment

- 6

- 7 Examples of products made from banana fiber fabric

- 8

- 9 How can I get involved in banana fiber entrepreneurship?

A guide to the process and benefits of making banana fiber fabric from banana tree waste

Prof. Aécio D’Silva, Ph.D

AquaUniversity

Banana fiber fabric is a natural, biodegradable, and sustainable textile that can be made from the discarded parts of the banana tree. Learn how to make it and why it is good for you and the planet. This fiber is a type of fabric that is made from the fibers extracted from the stem and bark of the banana tree. It is a natural, biodegradable, and sustainable textile that can be used for various purposes such as clothing, accessories, home decor, and paper. This fiber has many advantages over conventional fabrics such as cotton, silk, or polyester. It is soft, durable, breathable, antibacterial, and UV-protective. It also helps to reduce waste, conserve water, and support rural livelihoods.

In this Collaborative Intelligence post, we will explain how to make fiber fabric from banana tree waste, step by step. We will also discuss the benefits of this fiber fabric for you and the environment, and some examples of products made from it.

How to make fabric from banana tree waste

Making this fiber from banana tree waste is a simple and eco-friendly process that involves the following steps:

Step 1: Harvesting the banana tree waste

The first step is to harvest the banana tree waste, which is the stem and bark of the banana tree that remains after the banana fruit is harvested. This waste is usually discarded or burned, but it can also be used to make banana fiber fabric. The banana tree waste can be collected from banana plantations or farms or bought from local farmers.

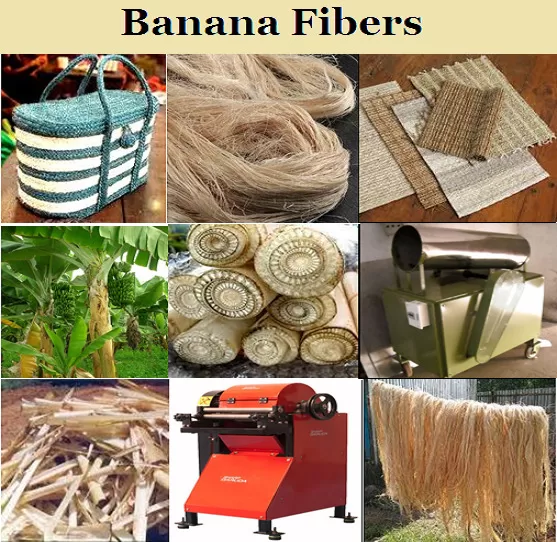

Step 2: Extracting the banana fibers

The second step is to extract the fibers from the banana tree waste. This can be done manually or mechanically. The manual method involves peeling off the outer layers of the stem and bark and scraping off the inner fibers with a knife or a tool. The mechanical method involves using a machine that separates the fibers from the stem and bark. The extracted fibers are then washed, dried, and combed to remove any impurities and knots.

Step 3: Spinning the banana fibers into yarn

The third step is to spin the fibers into yarn. This can be done by hand or by machine. The hand-spinning method involves twisting the fibers together using a spindle or a wheel. The machine spinning method involves using a machine that spins the fibers into yarn. The spun yarn is then wound into balls or skeins.

Step 4: Weaving or knitting the banana yarn into fabric

The fourth step is to weave or knit the banana yarn into fabric. This can be done by hand or by machine. The hand weaving or knitting method involves using a loom or needles to interlace or loop the yarn into the fabric. The machine weaving or knitting method involves using a machine that weaves or knits the yarn into fabric. The woven or knitted fabric is then cut, sewn, dyed, or printed to make various products.

Benefits for you and the environment

Banana fiber fabric has many benefits for you and the environment, such as:

- It is natural, biodegradable, and sustainable. It is made from natural and renewable resources that do not require pesticides, fertilizers, or chemicals. It is also biodegradable and compostable, which means it does not contribute to landfill or pollution. It is also sustainable, as it uses the waste parts of the banana tree that would otherwise be discarded or burned, and provides an alternative income source for rural farmers.

- It is soft, durable, breathable, antibacterial, and UV-protective. It has a soft and silky texture that is comfortable to wear and touch. It is also durable and resistant to wear and tear, which means it lasts longer and does not need frequent washing or ironing. It is also breathable and moisture-wicking, which means it keeps you cool and dry. It is also antibacterial and hypoallergenic, which means it prevents odors and infections. It is also UV-protective, which means it protects you from harmful sun rays.

- It is versatile and fashionable. It can be used for various purposes such as clothing, accessories, home decor, and paper. It can also be dyed, printed, or blended with other fibers to create different colors, patterns, and textures. It can also be styled and designed to suit different tastes and preferences. Banana fiber fabric is a versatile and fashionable textile that can enhance your wardrobe and lifestyle.

Examples of products made from banana fiber fabric

Banana fiber fabric can be used to make various products such as:

- Clothing: Banana fiber fabric can be used to make clothing such as shirts, dresses, skirts, pants, jackets, and scarves. Banana fiber clothing is comfortable, durable, breathable, antibacterial, and UV-protective, making it ideal for casual, formal, or outdoor wear.

- Accessories: Banana fiber fabric can be used to make accessories such as bags, hats, belts, wallets, and jewelry. Banana fiber accessories are stylish, durable, eco-friendly, and unique, making them perfect for adding some flair to your outfit.

- Home decor: Banana fiber fabric can be used to make home decor such as curtains, cushions, rugs, tablecloths, and wall hangings. Banana fiber home decor is cozy, elegant, sustainable, and biodegradable, making it suitable for decorating your home.

- Paper: Banana fiber fabric can be used to make paper such as notebooks, cards, envelopes, and wrapping paper. Banana fiber paper is smooth, strong, natural, and recyclable, making it ideal for writing, drawing, or wrapping.

How can I get involved in banana fiber entrepreneurship?

Banana fiber entrepreneurship is a way of creating value-added products from the waste parts of the banana tree, such as the stem and bark. Banana fiber products are natural, biodegradable, and sustainable, and can be used for various purposes such as clothing, accessories, home decor, and paper. Banana fiber entrepreneurship can also provide income and empowerment for rural communities, especially women and youth, who can use their skills and creativity to produce and market various products.

If you are interested in getting involved in banana fiber entrepreneurship, you can follow these steps:

- Learn about the process and benefits of making banana fiber products. You can read some articles online, such as this one

or this one

or watch some videos on YouTube.

- Find a source of banana tree waste. You can contact local farmers or banana plantations and ask them if they are willing to sell or donate their banana tree waste. You can also look for banana tree waste in markets or waste collection centers.

- Get the equipment and materials needed to extract and process the banana fibers. You will need a machine that can separate the fibers from the stem and bark, or a tool that can do it manually. You will also need a machine or a tool that can spin the fibers into yarn, and a loom or needles that can weave or knit the yarn into fabric. You can buy these equipment and materials online or look for local suppliers or manufacturers.

- Learn the skills and techniques needed to make banana fiber products. You can enroll in a training course or a workshop that teaches you how to extract, spin, weave, or knit the banana fibers. You can also learn from online tutorials, such as this one or this one.

- Create your own banana fiber products. You can use your imagination and creativity to make different products, such as slippers, hats, bags, curtains, rugs, notebooks, cards, and more. You can also dye, print, or blend the banana fibers with other fibers to create different colors, patterns, and textures.

- Market and sell your banana fiber products. You can sell your products online, through platforms such as Etsy or Amazon, or offline, through local shops, fairs, or exhibitions. You can also promote your products through social media, blogs, or word-of-mouth. You can also partner with associations, companies, or cooperatives that support banana fiber entrepreneurship, such as Bangalore Greenkraft or Green Banana Paper.

Get started with banana fiber entrepreneurship it is a rewarding and eco-friendly way of making use of banana tree waste and creating value-added products.

In conclusion, banana fiber fabric is a natural, biodegradable, and sustainable textile that can be made from the discarded parts of the banana tree. It is a simple and eco-friendly process that involves harvesting the banana tree waste, extracting the banana fibers, spinning the banana fibers into yarn, and weaving or knitting the banana yarn into fabric. Banana fiber fabric has many benefits for you and the environment, such as being soft, durable, breathable, antibacterial, and UV-protective. It can also be used for various purposes such as clothing, accessories, home decor, and paper. Banana fiber fabric is a versatile and fashionable textile that can transform your wardrobe and lifestyle.

References:

[1] Banana fibre: A boon for rural women. (2019, July 29). Retrieved from https://www.fao.org/fao-stories/article/en/c/1203745/

[2] Nair, S., & Jayasree, A. K. (2014). Extraction and characterization of banana pseudo stem fibers. International Journal of Engineering Research and Technology, 3(8), 1080-1084.

[3] Kumar, K. S., & Bhowmik, D. (2012). Banana fibre-reinforced biodegradable soy protein composites. Journal of Reinforced Plastics and Composites, 31(4), 241-252.

[4] Banana Fiber Products. (n.d.). Retrieved from https://www.bananafiberproducts.com/