Contents

- 1 Learn the PDCA 4-Step Process for Implementing a Culture of Continuous Improvement in Your Organization

- 2 By Aécio D’Silva, PhD(1), Maécia Moura, MSc(2), Fabiano Moura, MSc(3)

- 3 PDCA – Culture of Continuous Improvement – What is?

- 4 PDCA – Culture of Continuous Improvement – When To Use?

- 5

- 6 PDCA – Continuous Improvement Cycle – How does it work?

- 7 Examples Of Companies Implementing the PDCA Cycle – Continuous Improvement

Learn the PDCA 4-Step Process for Implementing a Culture of Continuous Improvement in Your Organization

By Aécio D’Silva, PhD(1), Maécia Moura, MSc(2), Fabiano Moura, MSc(3)

(1) Moura Enterprises, AquaUniversityTucson, AZ 85742, EUA; (2) Signature Dental Partners, Fênix, AZ 85008; (3) Profound Commerce, Inc. Austin, TX 78746.

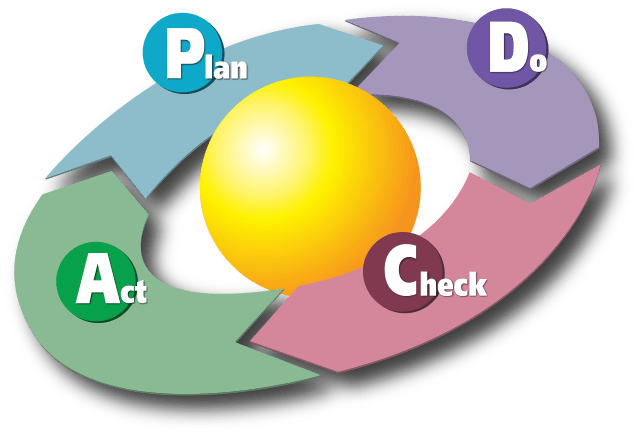

PDCA (Plan-Do-Check-Act) Deming Cycle is a continuous improvement process that helps organizations improve their products, services, and processes. By following the four-step process of PDCA, organizations can identify areas for improvement, implement changes, and monitor the results to achieve continuous improvement

PDCA – Culture of Continuous Improvement – In today’s fast-paced business environment, organizations must continually improve to remain competitive. One way to achieve this is by adopting a culture of continuous improvement. PDCA (Plan-Do-Check-Act) Deming Cycle is a proven process for continuous improvement that has been used by organizations worldwide for over 50 years.

Another version of this PDCA cycle is OPDCA. That is, it has five stages. The added “O” means to observe or, as some versions say, “Observe the current condition.” This emphasis on observation and the current condition is most applied in Lean management and the Toyota Production System. In this blog post, we will explore the four PDCA steps recommended in LAQLS Way Management and how you can use them to achieve continuous improvement in your organization/enterprise.

PDCA – Culture of Continuous Improvement – What is?

PDCA (Plan-Do-Check-Act) Deming Cycle is a four-step process that helps organizations achieve continuous improvement. Developed by quality management expert Dr. W. Edwards Deming (1), the PDCA process involves identifying a problem or area for improvement, developing a plan to address it, implementing the plan, and then evaluating the results to determine whether further improvements can be made.

PDCA – Culture of Continuous Improvement – When To Use?

The PDCA cycle is a versatile tool for many enterprise use cases, and must mostly be used when:

- When kicking off a new company or process/product improvement project.

- During the development of a new or optimized process, product, or workflow design.

- When defining and documenting a manual, tedious workflow, or task.

- When planning data analytics collection, tracking, and analysis to help identify core issues and drop-offs.

- During a change implementation.

- When migrating to a new system or workflow.

- When continuously identifying new areas of improvement.

- Starting a new improvement project

- Developing a new or improved design of a process, product, or service

- Defining a repetitive work process

- Planning data collection and analysis in order to verify and prioritize problems or root causes.

- Implementing any change

- Working toward continuous improvement

PDCA – Continuous Improvement Cycle – How does it work?

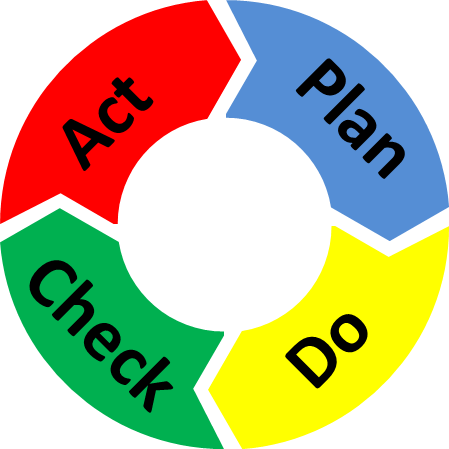

Because the PDCA cycle is divided into four stages: Plan, Do, Check, and Act, each step is important and must be performed carefully to ensure the effectiveness of the process. (2)

Step 1: Plan

The first step in the PDCA process is to Plan. During this step, you identify the problem or area for improvement and develop a plan to address it. This includes defining the problem, setting goals, identifying resources needed, and developing a timeline for implementation. The goal of the Plan step is to ensure that everyone involved understands the problem and the proposed solution.

Paragraph: For example, let’s say that customer satisfaction surveys have indicated that customers are unhappy with how long it takes to respond to their inquiries. During the Plan step, you would identify the specific issues causing the delay, set a goal to reduce response times, identify the resources needed to make the necessary changes and develop a timeline for implementation.

Step 2: Do

The second step in the PDCA process is to Do. During this step, you implement the plan that was developed in the first step. This may involve making changes to processes, procedures, or products, or introducing new practices or tools. The goal of the Do step is to test the effectiveness of the proposed solution.

Paragraph: In the example, we used earlier, during the Do step, you would implement the changes identified in the Plan step. This may include training staff on new procedures, using new technology to improve response times, or revising the workflow to improve efficiency. By implementing these changes, you can test their effectiveness and identify any issues that need to be addressed.

Step 3: Check

The third step in the PDCA process is to Check. During this step, you evaluate the results of the changes made during the Do step. This involves measuring and analyzing the data to determine whether the changes had the desired effect. The goal of the Check step is to identify any areas where further improvements can be made.

Paragraph: Continuing with our earlier example, during the Check step, you would evaluate the results of the changes made during the Do step. You may measure response times before and after the changes were implemented, analyze customer feedback, or review other metrics related to the issue. By doing so, you can determine whether the changes had the desired effect and identify any areas where further improvements can be made.

Step 4: Act

The fourth and final step in the PDCA process is to Act. It involves implementing new changes based on the previous step’s results. This may involve making further revisions. It is important that changes are implemented based on accurate data and that the results of previous changes are evaluated to ensure the effectiveness of new changes.

The PDCA process is cyclical, meaning that once the fourth step (Act) is completed, organizations start again at the first step (Plan). This allows organizations to continually improve and refine their products, services, and processes over time.

Examples Of Companies Implementing the PDCA Cycle – Continuous Improvement

The PDCA (Plan-Do-Check-Act) cycle is a powerful tool for continuous improvement in businesses and organizations. Many companies have successfully implemented the PDCA cycle to improve their processes, products, and services. Let’s take a look at some examples of companies that have successfully used the PDCA cycle:

Toyota: One of the most famous examples of a company that uses the PDCA cycle is Toyota. Toyota uses the PDCA cycle in its production process to continually improve quality and efficiency. By constantly evaluating its processes and implementing changes based on data-driven insights, Toyota has become one of the most successful and respected car manufacturers in the world.

Amazon: Amazon is another company that uses the PDCA cycle to improve its operations. For example, Amazon uses data analysis to identify areas of its website that are causing customers to abandon their shopping carts. By implementing changes based on this data, Amazon has improved its checkout process and increased its sales.

Procter & Gamble: Procter & Gamble, a consumer goods company, uses the PDCA cycle to improve the quality of its products. For example, when P&G noticed a high number of customer complaints about a certain shampoo, they used the PDCA cycle to identify the problem, develop a plan to address it, implement changes to the product, and evaluate the results. As a result, P&G was able to improve the quality of the shampoo and reduce the number of customer complaints.

McDonald’s: McDonald’s uses the PDCA cycle to improve the quality of its food and service. For example, when McDonald’s noticed that customers were unhappy with the quality of its French fries, they used the PDCA cycle to identify the problem, develop a plan to address it, implement changes to the production process, and evaluate the results. As a result, McDonald’s was able to improve the quality of its fries and increase customer satisfaction.

In conclusion, the PDCA cycle of Continuous Improvement is a powerful tool to achieve continuous improvement in organizations. By following the four-step PDCA process, organizations can identify areas for improvement, implement change, and monitor results to achieve continuous improvement. By implementing the process of identifying problems, developing plans, making changes, and evaluating results, companies such as Toyota(3), Amazon, Procter & Gamble, and McDonald’s have been able to achieve significant improvements and success. As the business environment continues to evolve, adopting a culture of continuous improvement through processes like PDCA can truly drive organizations to remain continuously competitive, innovative, and successful.

References:

(1)Deming, W. Edwards (1986). Out of the crisis. Cambridge, MA: Massachusetts Institute of Technology, Center for Advanced Engineering Study. p. 88. ISBN 978-0911379013. OCLC 13126265.

(3)Liker, Jeffrey K. 2021. Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer. 2nd ed. New York: McGraw Hill. https://www.accessengineeringlibrary.com/content/book/9781260468519