Contents

- 1 A Deep Dive into the World of EV Battery Swapping Technology

- 2 Prof. Aécio D’Silva, Ph.D AquaUniversity

- 3 As electric vehicles (EVs) gain momentum in the automotive industry, innovative solutions like battery swapping emerge as game-changers, potentially revolutionizing how we “refuel” our cars

- 4 Advantages of Battery Swapping: Quick and Convenient

- 5 Hurdles to Overcome: Standardization and Infrastructure

- 6 Types of Battery Swapping Systems: Automated vs. Manual

- 7 Comparing Swapping to Recharging: Efficiency vs. Ubiquity

- 8 The Cost Factor: Economic Considerations

- 9

- 10 Feasibility of Battery Swapping for EVs: A Viable Alternative?

- 11 What are the environmental implications of battery swapping?

- 12

- 13 How can we improve the sustainability of battery production for EVs?

- 14 What are some innovative battery chemistries that have a lower environmental impact?

- 15

- 16 How close are we to commercializing solid-state batteries?

A Deep Dive into the World of EV Battery Swapping Technology

Prof. Aécio D’Silva, Ph.D

AquaUniversity

As electric vehicles (EVs) gain momentum in the automotive industry, innovative solutions like battery swapping emerge as game-changers, potentially revolutionizing how we “refuel” our cars

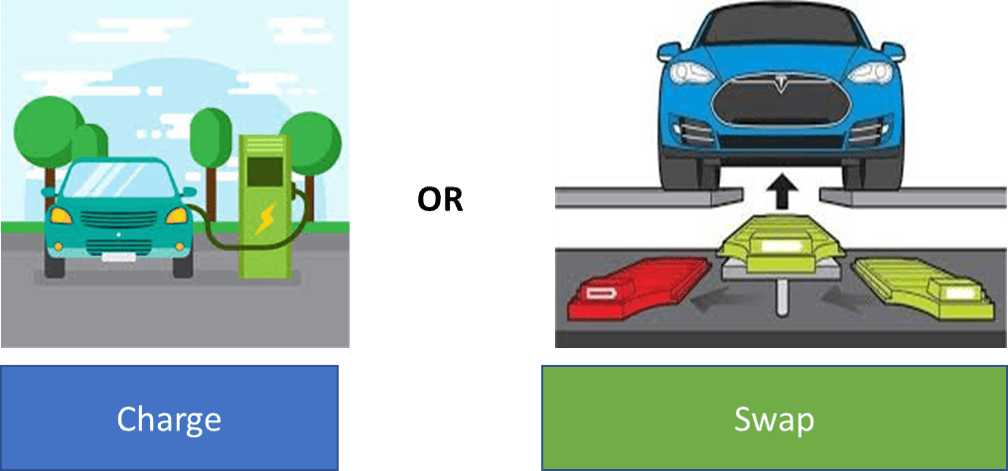

Battery Swapping – The concept of battery swapping for electric vehicles (EVs) is simple: instead of charging the battery, replace it with a fully charged one. This idea promises to address some of the most significant challenges facing EV adoption, including long charging times and range anxiety. This Intelligent Collaborative post examines the advantages, hurdles, types, status, and costs associated with battery swapping, comparing it to traditional recharging methods to determine its feasibility.

Advantages of Battery Swapping: Quick and Convenient

Battery swapping offers a significant time advantage over traditional charging methods. A swap can be completed in a matter of minutes, akin to the convenience of refueling a gasoline vehicle, making long trips more feasible for EV drivers.

Hurdles to Overcome: Standardization and Infrastructure

One of the main challenges for battery swapping is the lack of standardization across different EV models and manufacturers. Additionally, building the necessary infrastructure for swapping stations requires substantial investment and coordination.

Types of Battery Swapping Systems: Automated vs. Manual

There are generally two types of battery swapping systems: automated, where machinery swaps the battery without human intervention, and manual, which requires technicians to replace the battery.

Current Status of Battery Swapping: Pioneers and Progress

While not yet widespread, several companies are pioneering battery swapping technology. Notable examples include Tesla’s early trials and Nio’s growing network of swap stations in China.

Comparing Swapping to Recharging: Efficiency vs. Ubiquity

Battery swapping may be faster, but recharging infrastructure is more ubiquitous and improving rapidly with advancements in fast-charging technology.

The Cost Factor: Economic Considerations

The cost of setting up and maintaining battery swapping stations is high, and there’s also the question of how to price battery swaps compared to traditional charging.

Feasibility of Battery Swapping for EVs: A Viable Alternative?

Whether battery swapping is a feasible technology for EVs depends on various factors, including consumer acceptance, economic viability, and advancements in battery technology.

What are the environmental implications of battery swapping?

Battery swapping presents opportunities for reducing the operational carbon footprint of EVs, it also introduces challenges that need to be addressed through sustainable practices and technological advancements. The environmental implications of battery swapping for electric vehicles (EVs) are multifaceted. Here are some key points to consider:

- Production Emissions: The production of EV batteries is a carbon-intensive process, accounting for a significant portion of an EV’s total production emissions. This includes emissions from mining and refining raw materials like lithium, cobalt, and nickel, as well as the manufacturing of the batteries themselves.

- Recycling and Disposal: As the adoption of EVs increases, so does the need for sustainable recycling and disposal methods for old batteries. Improper disposal can lead to environmental hazards, as batteries contain substances that can harm land and groundwater. Recycling can mitigate these risks and help address resource depletion concerns by recovering valuable materials.

- Lifecycle Analysis: It’s essential to consider the entire lifecycle of batteries, from production to disposal. While battery swapping can reduce the downtime of EVs and potentially extend the overall lifespan of the batteries, the environmental benefits depend on the efficiency and sustainability of the entire system.

- Decarbonization Efforts: Manufacturers are working to reduce the carbon footprint of battery production by investing in cleaner energy sources and more efficient manufacturing processes. This could significantly lower the environmental impact of battery swapping systems in the future.

How can we improve the sustainability of battery production for EVs?

Improving the sustainability of battery production for electric vehicles (EVs) involves several key strategies:

- Use of Renewable Energy: Shifting battery production processes to rely on renewable energy sources, such as solar or wind power, can significantly reduce carbon emissions associated with manufacturing.

- Recycling and Reuse: Developing efficient recycling processes for end-of-life batteries can recover valuable materials and reduce the need for new raw material extraction.

- Sustainable Material Sourcing: Sourcing materials responsibly and increasing the use of recycled materials in battery production can minimize environmental impact.

- Design for Recycling: Designing batteries with recycling in mind, including standardizing battery chemistries and improving ease of disassembly, can make recycling more practical and sustainable.

- Energy Efficiency: Improving the energy efficiency of battery manufacturing processes can reduce overall energy consumption and, consequently, carbon emissions.

- Supply Chain Decarbonization: Reducing the carbon footprint of the supply chain by optimizing logistics, using low-emission transport options, and sourcing locally where possible can contribute to sustainability.

- Closed-Loop Manufacturing: Implementing closed-loop manufacturing processes to reduce waste and increase the use of recycled materials can lead to more sustainable production practices.

- Longer-Lasting Batteries: Developing more efficient and longer-lasting batteries can reduce the frequency of battery replacement and the associated environmental impact.

By focusing on these areas, the EV industry can move towards more sustainable battery production, contributing to the overall reduction of the environmental impact of electric mobility.

What are some innovative battery chemistries that have a lower environmental impact?

These innovative battery chemistries are part of ongoing efforts to improve sustainability by developing efficient manufacturing processes, responsible sourcing, promoting recycling, and exploring alternative battery chemistries. These efforts are very important for the electric vehicle industry due to their aim to have a lower environmental impact. These innovative battery chemistries are being actively researched and developed. Here are a few examples:

- Solid-State Batteries: These batteries replace the liquid electrolyte with a solid one, which can lead to higher energy density, faster charging times, and improved safety due to reduced flammability risks.

- Sodium-Ion Batteries: Utilizing abundant materials like sodium, which can be derived from table salt, sodium-ion batteries present a promising alternative to lithium-ion batteries. They offer a similar climate impact without the risk of depleting raw materials.

- Lithium-Sulfur Batteries: This type of battery chemistry has a higher energy density and is less reliant on cobalt and nickel, which are associated with environmental and ethical concerns.

- Nickel-Manganese-Cobalt (NMC) Batteries: Efforts to reduce the cobalt content in NMC batteries are ongoing, aiming to lessen the environmental and social impact of cobalt mining.

- Lithium-Iron-Phosphate (LFP) Batteries: These batteries are known for not containing cobalt or nickel, which makes them less environmentally damaging and more stable.

- Magnesium-Ion Batteries: Magnesium is more abundant than lithium, and magnesium-ion batteries have the potential for higher energy density and environmental friendliness.

- Organic Batteries: Using organic materials for electrodes, these batteries can be more sustainable and environmentally friendly, as they are based on carbon, which is abundant and has a lower environmental impact.

The goal is to find solutions that meet the energy demands while minimizing the environmental footprint.

How close are we to commercializing solid-state batteries?

The commercialization of solid-state batteries (SSBs) is also a topic of significant interest in the electric vehicle industry due to their potential advantages over traditional lithium-ion batteries. Recent advancements suggest that while SSBs are not yet widely commercialized, there is considerable progress in research and development aimed at overcoming the current limitations.

Several companies and research institutions are actively working on developing SSBs for practical applications. Efforts are focused on improving membrane production strategies, cost-effectiveness, and eco-friendliness, as well as enhancing safety and energy density. Some small-scale commercialization has already begun, mostly for low-power applications like sensors connected to the Internet.

Major automotive companies like Toyota, Nissan, and Honda, along with U.S.-based startups such as Solid Power and QuantumScape, are also working towards commercializing SSBs in the near term.

However, challenges such as cost reduction, mass production, and ensuring long-term reliability still need to be addressed before SSBs can be fully commercialized for widespread use in electric vehicles.

In summary, while the exact timeline for the widespread commercialization of SSBs is uncertain, the industry is making strides toward making this technology viable, with some expecting significant developments by the end of this decade.

In conclusion, this Collaborative Intelligence post provides a comprehensive overview of battery swapping for EVs, weighing its pros and cons and the sustainability of battery production to assess its potential as a mainstream solution for the future of transportation.

Battery swapping for EVs presents an intriguing alternative to traditional charging, offering the potential for faster “refueling” times and greater convenience. However, its success hinges on overcoming significant hurdles such as standardization and infrastructure development. As the EV market continues to evolve, battery swapping may become a viable option alongside fast charging, contributing to the broader adoption of electric vehicles.

References:

- Lee, H., & Kim, J. (2024). Pricing strategies of a battery swapping service for electric vehicles. Transportation Research Part D: Transport and Environment, 129, 104142. https://doi.org/10.1016/j.trd.2024.104142

- “Battery swapping technology and its impact on the electric vehicle market, “Energy Policy. https://chambers.com/articles/battery-swapping-a-promising-future-for-electric-vehicles

- Findings of New Lifecycle Assessment on Auto Batteries: Lead Battery Manufacturing as Significantly Lower Environmental Impact Than Lithium-Iron Phosphate. https://batterycouncil.org/auto-batteries-lca-lead-battery-manufacturing-has-significantly-lower-environmental-impact-than-lithium-iron-phosphate/.

- https://www.sae.org/news/2023/11/solid-state-battery-status .

- https://pubs.rsc.org/en/content/articlelanding/2024/qm/d3qm01171b .

- https://www.sae.org/news/2023/11/solid-state-battery-status

- https://www.thermofisher.com/blog/materials/accelerating-new-battery-technology-innovation/.