Contents

- 1 Catalytic hydrothermal liquefaction (CHTL) is a process that can convert wet algae biomass into biocrude oil and biochemicals, a renewable and sustainable alternative to fossil fuels

- 2 Prof. Aécio D’Silva, Ph.D AquaUniversity

- 3 The advantages of Catalytic Hydrothermal Liquefaction Technology for biocrude production from algae

- 4

- 5 The principles and parameters of CHTL for biocrude production from algae

- 6 Some of the challenges of CHTL for biocrude production from algae are:

- 7

- 8 How does CHTL compare to other biofuel technologies?

- 9 References:

Catalytic hydrothermal liquefaction (CHTL) is a process that can convert wet algae biomass into biocrude oil and biochemicals, a renewable and sustainable alternative to fossil fuels

Prof. Aécio D’Silva, Ph.D

AquaUniversity

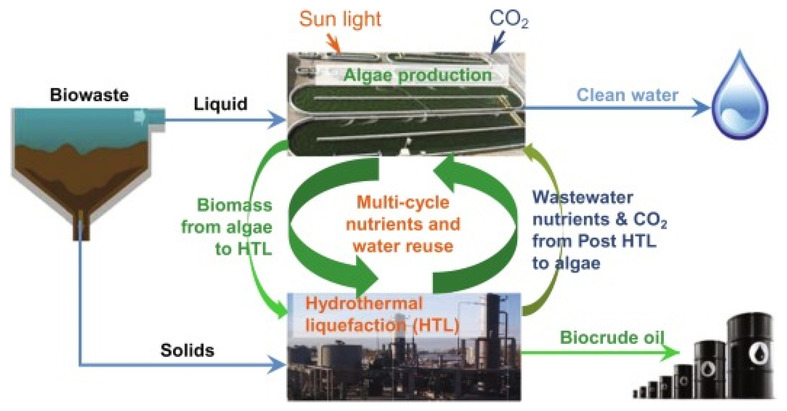

Catalytic Hydrothermal Liquefaction Technology (CHTL) can overcome the challenges of conventional biofuel production, such as high energy consumption, low conversion efficiency, and poor biocrude quality. CHTL can also utilize various types of algae, such as microalgae, macroalgae, and cyanobacteria, which have high biomass productivity, low land and water requirements, and high environmental benefits.

Algae are aquatic organisms that can perform photosynthesis and produce biomass, which can be converted into biofuels, such as biogas, bioethanol, biodiesel, biocrude oil, from which a range of low-carbon transportation fuels, biochemicals, and biomaterials can be made. Microalgal biomasses serve as exceptional reservoirs of a variety of biochemicals and bioactive compounds, including lipids, polysaccharides, carotenoids, vitamins, phenolics, and phycobiliproteins.

Biofuels, low-carbon transportation fuels, are renewable and sustainable sources of energy that can reduce greenhouse gas emissions, enhance energy security, and diversify the energy portfolio. However, biofuel production from algae also faces some challenges, such as high moisture content, low lipid content, complex cell wall structure, and diverse biomass composition, which can affect the conversion process and the biocrude quality. (1)

Catalytic hydrothermal liquefaction (CHTL) is a process that can convert wet algae biomass into biocrude oil, a liquid fuel that can be refined and upgraded into transportation fuels, such as gasoline, diesel, or jet fuel. CHTL can overcome the challenges of conventional biofuel production, such as high energy consumption, low conversion efficiency, and poor biocrude quality, by using water as a reaction medium, catalysts as reaction promoters, and high temperature and pressure as reaction drivers. Catalytic Hydrothermal Liquefaction (CHTL) can also utilize various types of algae, such as microalgae, macroalgae, and cyanobacteria, which have high biomass productivity, low land and water requirements, and high environmental benefits. (2)

In this blog post, we will explore the advantages, principles, parameters, and applications of CHTL, and provide some examples and recommendations for its use and development.

The advantages of Catalytic Hydrothermal Liquefaction Technology for biocrude production from algae

Recently, India’s Reliance Industries Ltd showcased its cutting-edge algae-to-fuel technology in a video on the social media platform Instagram. The company has successfully operated large algae raceway ponds for the past five years near Jamnagar, converting sunlight, CO2, and seawater into bio-oil. They demonstrated the use of catalytic hydrothermal liquefaction technology to convert algae biomass into oil, allowing for the direct use of wet biomass without drying, ensuring the conversion of every organic fragment into oil without wastage. (3a)

Consequently, CHTL has demonstrated several advantages over other biofuel production methods, such as transesterification, pyrolysis, or gasification, such as high biocrude yield, low energy input, wide feedstock range, and high biocrude quality.

CHTL has several advantages over other biofuel production methods, such as:

- High biocrude yield: CHTL can achieve high biocrude yield, up to 80% of the dry biomass weight, by converting not only the lipids, but also the proteins, carbohydrates, and other components of the algae biomass into biocrude oil. CHTL can also reduce the formation of undesired by-products, such as char, gas, or aqueous phase, by using catalysts that can enhance the reaction kinetics, selectivity, and stability.

- Low energy input: CHTL can reduce the energy input, by using wet algae biomass, with a moisture content of 50-90%, without any prior drying or dewatering steps, which can consume up to 75% of the total energy input. CHTL can also recover the heat and the water from the reaction products, by using heat exchangers, separators, or condensers, which can improve the energy efficiency and the water balance of the process. (4)

- Wide feedstock range: CHTL can utilize various types of algae, such as microalgae, macroalgae, and cyanobacteria, which have different biomass characteristics, such as size, shape, cell wall, composition, and growth rate. CHTL can also handle mixed or contaminated algae biomass, such as algae harvested from wastewater or seawater, which can contain impurities, such as salts, metals, or pathogens, by using catalysts that can tolerate or remove these impurities. (5)

- High biocrude quality: CHTL can produce high-quality biocrude oil, with high heating value, low oxygen content, low viscosity, and low acidity, by using catalysts that can upgrade the biocrude oil during the reaction, by removing or modifying the undesirable compounds, such as oxygen, nitrogen, sulfur, or metals, which can affect the biocrude stability, compatibility, and performance. CHTL can also produce valuable co-products, such as biochar, biogas, or biofertilizer, from the solid, gaseous, or aqueous phases, which can be used for soil amendment, energy generation, or nutrient recovery. (6)

The principles and parameters of CHTL for biocrude production from algae

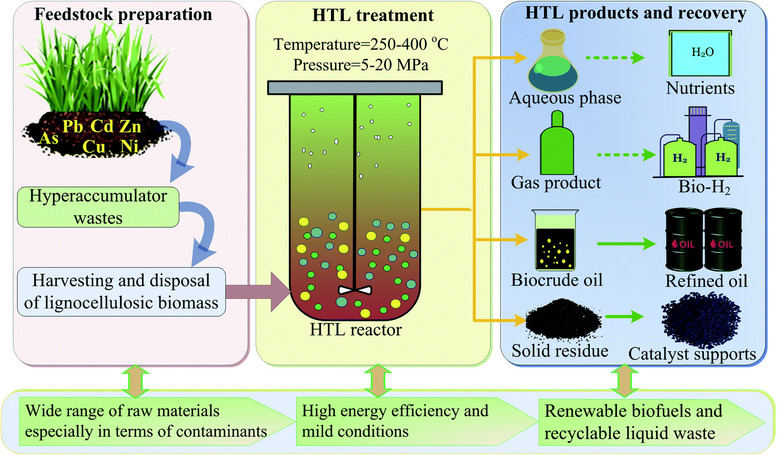

CHTL is based on the principles of hydrothermal liquefaction (HTL), which is a thermochemical conversion process that uses water as a reaction medium, and catalysts, which are substances that can accelerate or direct the reaction, without being consumed or changed. CHTL is influenced by various parameters, such as temperature, pressure, residence time, biomass-to-water ratio, and catalyst type and loading.

CHTL is influenced by the following parameters:

- Temperature: Temperature is the main parameter that determines the reaction rate, the biocrude yield, and the biocrude quality. The typical temperature range for CHTL is 250-400°C, which is sufficient to break down the biomass macromolecules, such as lipids, proteins, carbohydrates, and lignin, into smaller molecules, such as fatty acids, amino acids, sugars, and phenols, and then recombine them into biocrude oil. Higher temperatures can increase the biocrude yield and reduce the oxygen content, but also increase the char and gas formation, and degrade the biocrude quality. (7)

- Pressure: Pressure is the parameter that controls the water phase, the water density, and the water solvation power. The typical pressure range for CHTL is 10-25 MPa, which is required to maintain the water in a liquid or a supercritical state, which can dissolve the biomass components, facilitate the mass, and heat transfer, and prevent the vaporization of the biocrude oil. Higher pressures can increase the biocrude yield and quality, but also increase the energy consumption and the equipment cost. (8)

- Residence time: Residence time is the parameter that defines the duration of the reaction, the extent of the reaction, and the distribution of the reaction products. The typical residence time range for CHTL is 5-60 minutes, which is enough to complete the biomass decomposition and biocrude formation. Longer residence times can increase the biocrude yield and reduce the oxygen content, but also increase the char and gas formation, and degrade the biocrude quality.

- Biomass-to-water ratio: Biomass-to-water ratio is the parameter that affects the biomass concentration, the water availability, and the water dilution. The typical biomass-to-water ratio range for CHTL is 5-20%, which is optimal to achieve a high biocrude yield and quality, while avoiding the biomass slurry viscosity, the water scarcity, and the biocrude dilution. Higher biomass-to-water ratios can increase the biocrude yield and quality, but also increase the energy consumption and the equipment size.

- Catalyst type and loading: Catalyst type and loading are the parameters that influence the catalyst activity, selectivity, and stability, as well as the biocrude yield and quality. The typical catalyst types for CHTL are homogeneous catalysts, heterogeneous catalysts, or hybrid catalysts, which can be classified according to their phase, composition, or structure. Homogeneous catalysts are catalysts that are in the same phase as the reactants, such as acids, bases, or salts, which can enhance biomass hydrolysis, biocrude deoxygenation, or biocrude esterification. Heterogeneous catalysts are catalysts that are in a different phase than the reactants, such as metals, oxides, or carbides, which can enhance biomass hydrogenation, biocrude denitrogenation, or biocrude desulfurization. Hybrid catalysts are catalysts that combine the advantages of homogeneous and heterogeneous catalysts, such as supported catalysts, core-shell catalysts, or bifunctional catalysts, which can enhance the biomass conversion, the biocrude upgrading, or the catalyst recovery. The typical catalyst loading range for CHTL is 0.1-10%, which is optimal to achieve a high biocrude yield and quality, while avoiding catalyst deactivation, the catalyst leaching, or the catalyst poisoning.

Some of the challenges of CHTL for biocrude production from algae are:

- How to optimize the reaction conditions, such as temperature, pressure, residence time, and catalyst type, to maximize the biocrude yield and quality. (1, 9))

- How to reduce the energy and water consumption of the process, especially for the biomass pretreatment, dewatering, and biocrude upgrading steps, (9, 10)

- How to manage the by-products of the process, such as the aqueous phase, the residual solids, and the gaseous emissions, which may contain valuable nutrients, chemicals, or pollutants. (9, 11)

Researchers are working on various solutions to address these challenges, such as developing novel catalysts, integrating co-product recovery, and coupling CHTL with other conversion processes. (1, 9, 11). CHTL is a promising technology for producing sustainable biofuels from algae and other biomass sources.

How does CHTL compare to other biofuel technologies?

CHTL, or catalytic hydrothermal liquefaction, is a process that converts biomass, such as algae, into biocrude oil, a renewable and low-carbon energy source.

Compared to other biofuel technologies, CHTL has some advantages and disadvantages.

Some of the advantages are: (12)

- CHTL has a high conversion efficiency, as it can convert up to 80% of the biomass energy into biocrude oil.

- CHTL has low feedstock requirements, as it can use wet biomass without the need for drying or size reduction.

- CHTL is compatible with existing petroleum infrastructure, as the biocrude oil can be co-processed with conventional crude oil in refineries.

Some of the disadvantages are:

- CHTL requires a catalyst, which may be expensive, scarce, or prone to deactivation. (13)

- CHTL produces a biocrude oil that is acidic, unstable and contains impurities, such as nitrogen, sulfur, and oxygen.

- CHTL consumes a lot of energy and water, especially for the biomass pretreatment, dewatering, and biocrude upgrading steps,

Therefore, CHTL is a promising technology that can produce sustainable biofuels from biomass, but it also faces some challenges that need to be addressed by further research and development. (14)

Concluding, Catalytic hydrothermal liquefaction (CHTL) is a promising technology that can convert algae biomass to biocrude oil, a renewable and low-carbon energy source. CHTL has several advantages over other biomass conversion methods, such as high conversion efficiency, low feedstock requirements, and compatibility with existing petroleum infrastructure. However, CHTL also faces some challenges, such as catalyst selection and deactivation, biocrude quality and stability, and process optimization and integration. To overcome these challenges, further research and development are needed to improve the understanding of the CHTL reaction mechanism, kinetics, and thermodynamics, as well as to explore the potential of co-processing, co-liquefaction, and upgrading of the biocrude. CHTL is a promising technology that can contribute to the sustainable development of bioenergy and biorefinery. For more knowledge and practical information about converting algae into biofuels and biochemicals see our book ALGAE Coloring the Future Green on Amazon Books.

References:

(1) https://link.springer.com/article/10.1007/s12155-023-10615-5.

(2) https://www.nrel.gov/docs/fy13osti/58051.pdf.

(3) https://www.mdpi.com/2227-9717/10/2/207/htm.

(3a) https://www.instagram.com/reel/Cex2l2YIniD/

(4) https://pubs.rsc.org/en/content/articlelanding/2021/gc/d0gc02893b.

(5) https://link.springer.com/article/10.1007/s11356-020-11942-2.

(6) https://link.springer.com/chapter/10.1007/978-981-19-0680-0_5.

(7) http://www.osti.gov/bridge

(8) http://www.ntis.gov/help/ordermethods.aspx.

(9) https://www.energy.gov/sites/default/files/2021-04/beto-43-peer-review-2021-algae-anderson.pdf.

(10) https://link.springer.com/chapter/10.1007/978-981-15-1804-1_11.

(11) https://www.mdpi.com/1996-1073/14/21/6992.

(12) https://energsustainsoc.biomedcentral.com/articles/10.1186/s13705-014-0020-x.

(13) https://link.springer.com/article/10.1007/s10311-021-01273-0.

(14) https://bmcenergy.biomedcentral.com/articles/10.1186/s42500-019-0004-7.