By: Dr. John Kyndt ( Head Scientist of the Renewable Energy Program at Advanced Energy Creations Lab)

As current predictions go, the concept of algae for biofuels only becomes profitable if there is an economical use for the byproducts. Several applications have been suggested: from animal feedstock supplement to fertilizer and fermentation into ethanol.

None of these have been performed on a large scale and in some cases technological, environmental and regulatory issues could put up a barrier.

One other promising utilization of the lipid-extracted-algae (LEA) is to gasify them under controlled conditions into ‘synthesis gas’, also syngas (consisting primarily of carbon monoxide, carbon dioxide, and hydrogen).

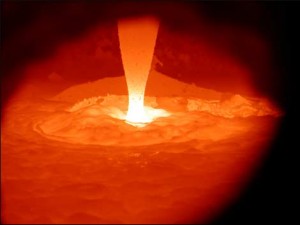

Several processes for the production of syngas from biomass or municipal waste have been established; however the most promising technology appears to be plasma arc based gasification.

The intense energy generated from a plasma torch will cause organic matter to break down and decompose. This process (called pyrolysis) basically breaks the molecular bonds of the components in the LEA or biomass, leaving only elements behind. Unlike incinerators, which use combustion to break down garbage, there is no burning, or oxidation, in this process. Therefore this is a much cleaner option.

Plasma waste converters can treat almost any kind of waste, including some traditionally difficult waste materials. Besides the syngas the only byproduct from the gasification process is vitrified material (slag), originating from inorganic material in the initial biomass material. Slag can be sold in any of its forms (depending on the cooling rate).

The rock form can be used as gravel or molded into bricks. Sand can be mixed with concrete and used in various paving and construction projects. Rock wool can be used for insulation.

Current technologies allow syngas to be further converted efficiently into ethanol or electricity. The syngas convertion into ethanol can be done either chemically (using a chemical catalyst) or biologically (using anaerobic bacteria). However innovative catalysts are being researched for the production of green gasoline, green jetfuel, and green diesel from syngas as well.

Syngas to ethanol

Currently over 90% of the ethanol production in the US comes from traditional grain fermentation processes using corn, wheat or barley. An alternative and much ‘greener’ and renewable approach is the production of ethanol from more sustainable sources of feedstock such as plant waste materials, e.g. wood waste, dried algae or LEA. These alternative biomasses do not interfere with human agriculture and food production as the currently used processes. It is also expected to create greater green house gas reductions and more carbon credits than the classic ethanol fermentation process.

There are 3 basic major steps in the biomass to ethanol conversion:

1. Production of syngas (CO, H2, CO2 and H2O) through the gasification of biomass feedstock.

2. Conversion of syngas to ethanol over chemical or bacterial catalyst.

3. Distillation of ethanol to obtain high purity (>99.5%).

Syngas to electricity

Electricity generation using syngas is as clean as electricity generation using natural gas. Therefore, pyrolysis of LEA into syngas, which can then be converted to electricity using a generator, is a clean, environmental friendly solution. Although co-firing algae biomass or LEA in existing coal-burning power plant already helps reduce sulfur dioxide and nitrogen oxide emissions, using pyrolysis would be a significant environmental improvement.

The waste conversion process using plasma arc technology produces no air emissions, nothing is released into the ground, and all the products of the process are completely reusable. So what is holding back the use of pyrolysis?

Commercially available plasma arc gasifiers are usually designed for a capacity of several tons of waste per day and, as you can expect, require a significant capital investment. Japan, Taiwan and Canada seem to have the lead in utilizing plasma arc gasification plants, however the US, Great Britain, Canada and China are planning to double the amount of plasma arc facilities for waste-to-energy conversion in the next few years.

As this emerging technology becomes more wide-spread, we believe that it will be a viable, far greener and more environmentally friendly utilization of LEA, with the bonus of generating additional fuel resources from the same amount of algae biomass.

[…] Algae after Lipids: Plasma Arc Based Gasification to Green Fuels […]