By: Dr. John Kyndt ( Head Scientist of the Renewable Energy Program at Advanced Energy Creations Lab) and Dr. Aecio D’Silva.

Although much debate is still going on what the most efficient way is to turn algae biomass into high yield fuel, one promising option is the extraction of oil out of the algae biomass first and using the lipid extracted algae (LEA) for syngas production in a second step.

Although much debate is still going on what the most efficient way is to turn algae biomass into high yield fuel, one promising option is the extraction of oil out of the algae biomass first and using the lipid extracted algae (LEA) for syngas production in a second step.

Depending on the triglyceride and hydrocarbon composition of the oil, the specific algal oil can be further processed for biodiesel through transesterification, or biojetfuel production through hydrocracking.

Syngas (‘synthetic gas’ or ‘synthesis gas’) can be generated by plasma arc based gasification of algae or LEA. The conversion of syngas into liquid fuel can be done either chemically (using a chemical catalyst) or biologically (using bacteria).

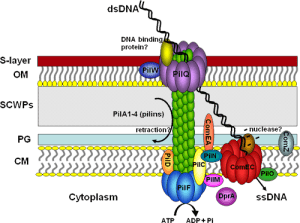

Laboratories in many parts of the world (including ours) are working diligently using genetic engineering (GE) techniques to generate thermophilic bacteria that can improve the current methods for syngas to fuel conversion, and novel algae strains with desired commercial properties that provide a better feedstock.

To design the improved thermophilic bacteria we focus on developing species that can tolerate optimal concentrations of syngas and ethanol (or butanol) and function at high temperature range in lab-scale fermenters.

In the case of algae optimization, laboratory-scale experiments need to be combined with pilot plant results to elucidate optimal parameters for the growth of the selected algae, extraction of the desired oil fraction, and quality analysis of the resulting oil.

By combining the power of biotechnology, through cutting-edge genetic engineering and proteomics, it is possible to develop high value products for the biofuel industry and markets. At the same time as designing optimized bacterial and algal species for pilot plants, it is desirable to develop a full cost model for the production of bioethanol, biodiesel and biojetfuel from syngas conversion.

All of these methods have to be optimized and their cost efficiency should be compared. The desired outcome of this work can provide cost-effective biodiesel, bioethanol and biojetfuel production, from waste biomass through syngas conversion or directly from microalgae.

A single integrated system will allow for high competitiveness with traditional petroleum-based fuel production. Continuous innovation and adaptation of the selected bacterial and algal species in the lab will be key to achieving this goal.

These are the basic steps to really develop a program to make algae-gas-to-fuel and algae-biomass-to-fuel a reality. Everyone who is involved in Algae for Biofuels programs must realize that the complete domain of these technologies is the cornerstone of our algae industry success.

[…] Developing GE Thermophilic Bacteria for Syngas to Fuel Conversion […]